News, 29 April 2022

News, 29 April 2022

Both cab side panels are now fully-welded and the filling / painting / flatting back has started. The intent is only to bring the entire bodyside up to a reasonable standard and then to go round again after all the body modifications are complete - for example the apertures for windows, grilles and vents are yet to be cut. The scabby tarpaulins and sheets protect the bogies and traction motors from filler powder which gets everywhere. The obvious gap in the valance / tumblehome at the lower edge of the bodyside will be filled in once the buffer shroud and cab footstep is finished.

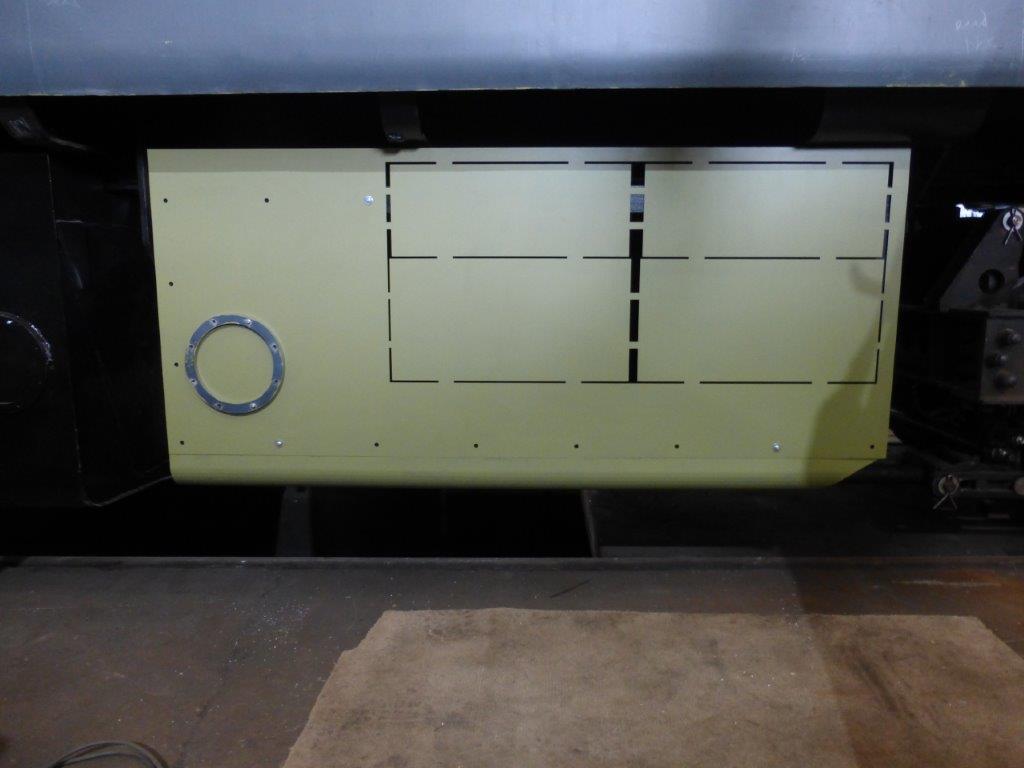

The dummy CWA (Carriage Warming Apparatus, i.e. boiler) water tank is as good as finished now. The (also dummy) tank contents gauge mounting boss is seen waiting its dummy gauge. The rectangular panels to the right of the tank are for (yes, you guessed) dummy inspection covers. The OE tanks had the engine starting battery within them and - mainly because this is a silly idea - we're not doing that, the appearance of the original tank will be maintained by the inclusion of false doors.

There were still areas on the loco which had yet to be attended, this is one of them; the cab footsteps. The step comprises an aluminium treadplate screwed to a steel plate itself welded on top of void formed from the load transfer plates under the door. It's a corrosion nightmare with bi-metallic action between the treadplate and lower plate and the void not having any ventilation to remove moisture. To be fair it's lasted nearly 60-years but the photo below shows how poor it was. The original lower plate is still attached, complete with the holes which let the water in.

The two thick (15mm) load transfer plates hadn't suffered too badly, they'd lost about 1mm off the thickness and a little off the top edge but they weren't going anywhere so they've been left in. The rust and other debris has been removed and two coats of black gloss applied to ensure that this assembly will outlast us all. Note also, the G clamp to the right which is holding a new pillar and backing plate in place ready for welding. The sharp-eyed will notice that the last bit of acb floor structure has now been removed (compare the photo above and below).

Finally for this update, a photo of the lower footstep plate from the outside of the loco, now fully-welded in. Also replaced are the bottom sections of the door seal closures which were very conveniently the same as 25 x 25 x 4 angle so a quick and easy job for once.